HOME / POSTS / ALUMINUM RUBIK'S CUBE

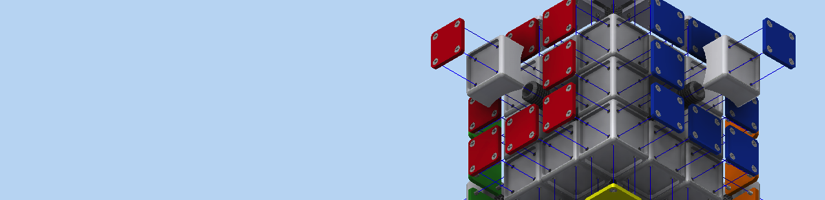

Aluminum Rubik's Cube

May 2016 Bianchini-Love

Project Documents

This is a long term project primarily for learning purposes and a novel product. I admire design and art, so this build can be considered an art project depending on the way you look at it. I'm working on this project with Bibit as my machining skills can easily use the help of an actual mechanical engineer. The goal is to create an Rubik's cubed machined out of aluminum that is the size of a standard Rubik's cube with 0.75" sub-cubes. Some adjustments are being made as the build progresses, so stay tuned for updates!

bianchini-love engineering

bianchini-love engineering